What are the advantages and disadvantages of plastic lenses?

发布时间 : 2023-08-12

The molding process of plastic optical lenses, especially the injection molding process of thermoplastic optical plastics, is completely different from the grinding and polishing process of glass optical lenses in the field of cold processing.

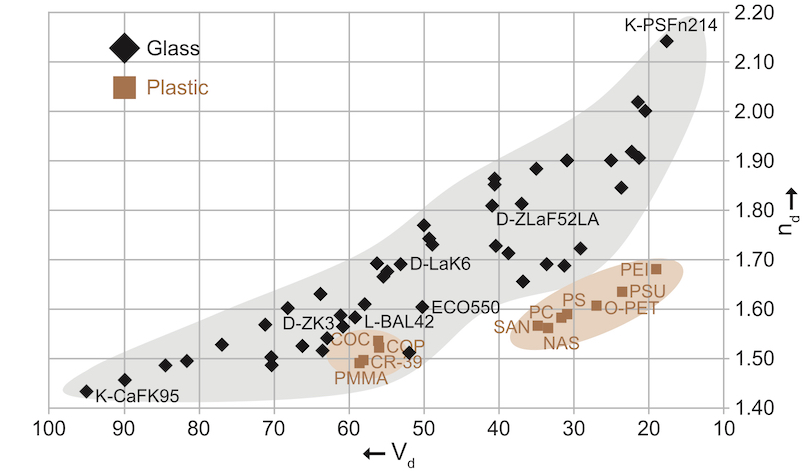

The design of plastic lens in the optical calculation and glass lens is not much different, it is important to consider the inherent performance and shortcomings of the plastic itself, mainly in the refractive index, temperature change, humidity change and birefringence four aspects.

(1) refractive index. The refractive index of a plastic lens varies with the shape of the lens and the molding method. After the lens is formed, its refractive index must be measured, and then the optical design is carried out according to the measured refractive index. When determining the shape of the lens, the feasibility and accuracy of mold processing, forming and measurement should be taken into account.

(2) Temperature change. The expansion coefficient of plastic is 10 times that of glass, and the temperature change of the surrounding environment will cause the focus displacement of the plastic lens. The solution is to make the plastic lens not bear the optical focal effect, that is, to form the dull focal optical system, or to form a synthetic differential optical system with the glass lens, so that the glass lens bears the main optical focal. At present, when plastic lenses are used in camera lenses, this measure is almost all used to compensate for the impact of temperature changes.

(3) Humidity change. Like temperature, when humidity changes, it will also cause the refractive index and curvature of the plastic lens to change, resulting in focus displacement and performance degradation. Unlike temperature changes, humidity changes slowly and over a long period of time. At present, most of the existing materials with minimal water absorption are selected as far as possible, and sealing measures are taken on the assembly structure to minimize the impact of humidity changes. Of course, improving the moisture resistance of plastic materials and developing new plastics are ideal goals to pursue.

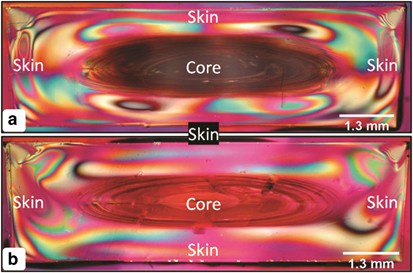

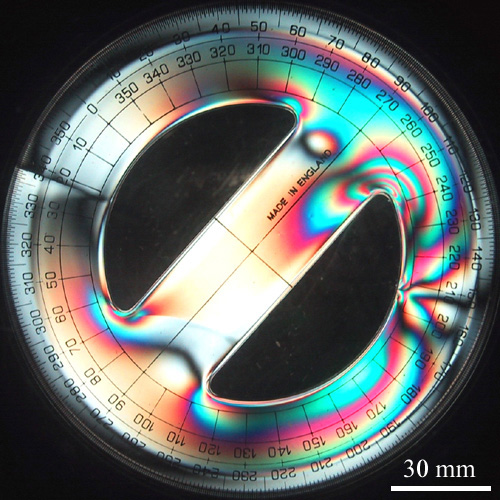

(4) Birefringence. Birefringence has great influence on stability. In general, the higher the dispersion of the material, the greater the birefringence, this important factor should be considered when choosing plastic materials. In addition to the material factors, the residual birefringence size of the plastic mirror is also different due to the different mold structure and forming conditions. Therefore, it is also very important to design a reasonable mold and determine the appropriate forming conditions.